Collaborative Innovation is an approach for rapid innovation of entire value chains. A value chain is a group of enterprises or organizations that offers a joint value proposition to the market. This may be an OEM and its supply chain or a consortium of co-operating companies.

Industrial products are practically always developed by specialized enterprises that work together. One of them makes a final product that is offered to end-users, others deliver (sub)systems, components, base materials or services such as design, financing, distribution or sales. Seen from the perspective of the final product producer, the collective is organized as a hierarchy: each main supplier (also called 1st tier supplier) may have other suppliers on its turn, called 2nd or 3rd tier suppliers. Together they form the supply chain.

Seen from the perspective of suppliers, the 'chain' is more like a network: most suppliers have multiple clients, often making different product types in different business processes.

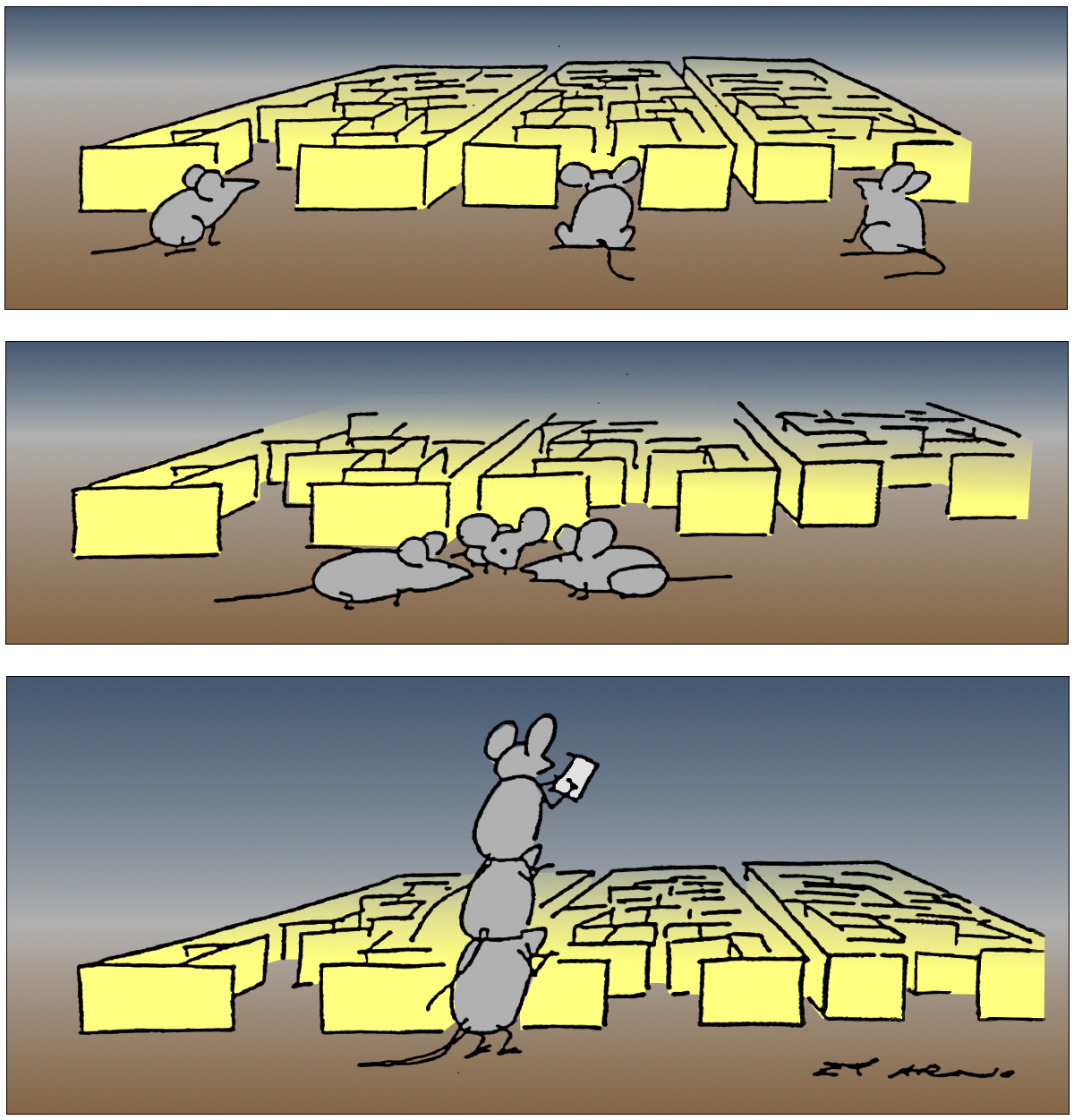

Many enterprises in a value chain have idea's for improved products or services which add more value to the final solution. It is however the enterprise at the end of the value chain that earns the money. This implies that such innovations cannot be succesful if the chain from innovative supplier to the final value selling enterprise does not co-operate. Nowadays it is recognized that idea's for improvement may emerge in any part of the chain and even by any employee of each supplier. Companies that do not exploit the full potential of its employees throughout the entire chain do not learn fast enough to meet the challenges of a sustainable future.

Innovation of a final product or service requires therefore close co-operation of all parties in the supply network, and the utilization of all the know-how that is available. This is the goal of Collaborative Innovation (CI). Foundation-CI offers a methodology that enables supply networks to design and implement product-, process- and business innovations in an efficient way, thus reducing their time-to-market.

Product and process innovation results from learning and improving. It requires knowledge of the present situation and of earlier attempts to change that may have failed. It is then important to understand what caused the failure so that a next attempt is more likely to become successful.

To understand learning, we discuss first the way in which human beings learn. For practical reasons four levels of learning are distinguished, in which each level builds further on top of a lower level:

3rd order team learning

System theory tells us that a whole can be more than the sum of its parts. But a whole can only be more than the sum of its parts if these parts have specialized functions (i.e. functions that other parts do not have) and when these parts interact. An organization such as an enterprise can indeed be more than the sum of its employees, if the employees fullfill different roles and collaborate. Collaboration requires communication however, and communication requires the use of a common language.

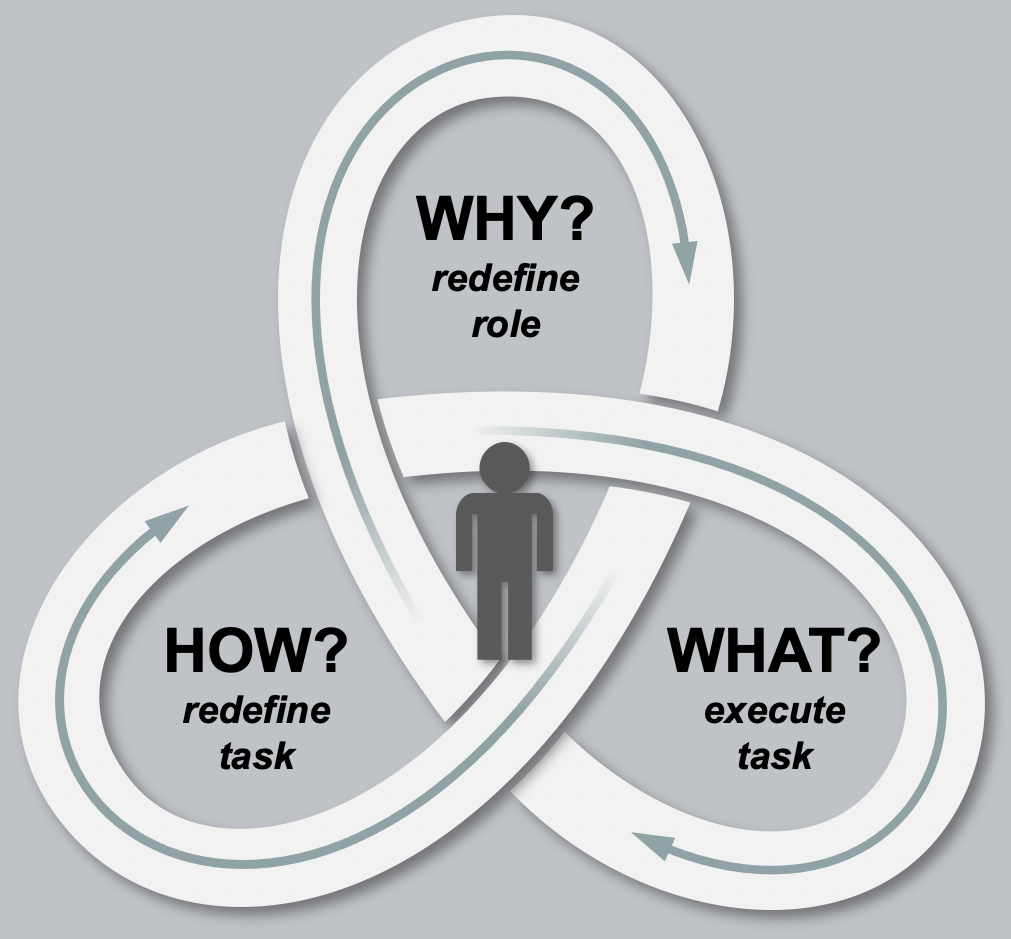

Collaborative Innovation is rooted in the modern sociotechnic approach in which workers fulfill a central role. This approach is characterized by integral management, and a process oriented organization of self-steering teams that take full responsibility for the end result. Where employees in traditional settings fullfill predefined job roles and are only oriented on the execution of tasks, they get the opportunity to develop their personal talents and to redefine their work in the new setting.

A trefoil - a flower with three leafs - depicts the self-steering process. An employee is responsible for the execution of work (lower right leaf), but also for the way in which it is carried out (lower left leaf), and for the role that he or she fulfils in the organization (upper leaf). This results in a cyclic process of continuous improvement, in which the employee strives to optimal job satisfaction and maximization of his or hers talents.

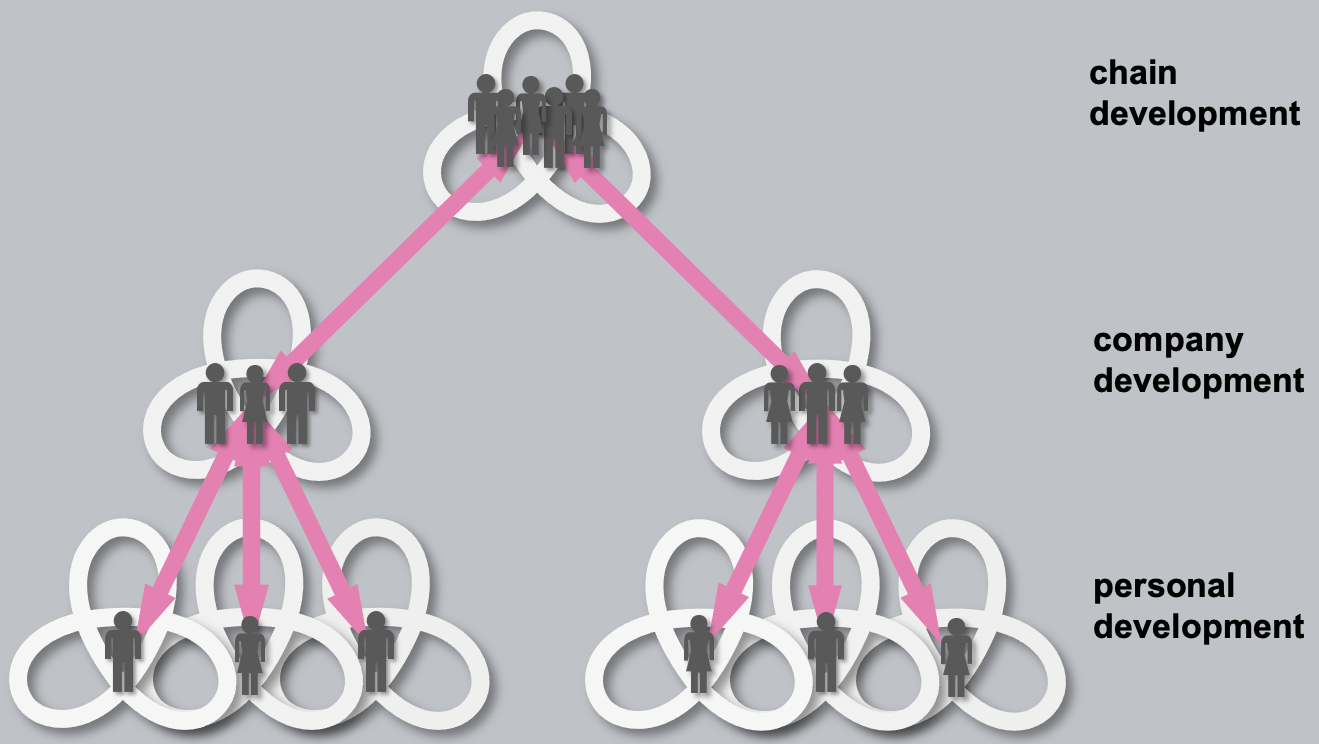

Continuous improvement can be done on a personal level, but also as a team, as a company, or as a group of companies which collaborate in a value chain. Hence the term Collaborative Innovation (CI). Innovation of value chains makes only sense if the companies involved agree about long term (i.e. strategic) co-operation.

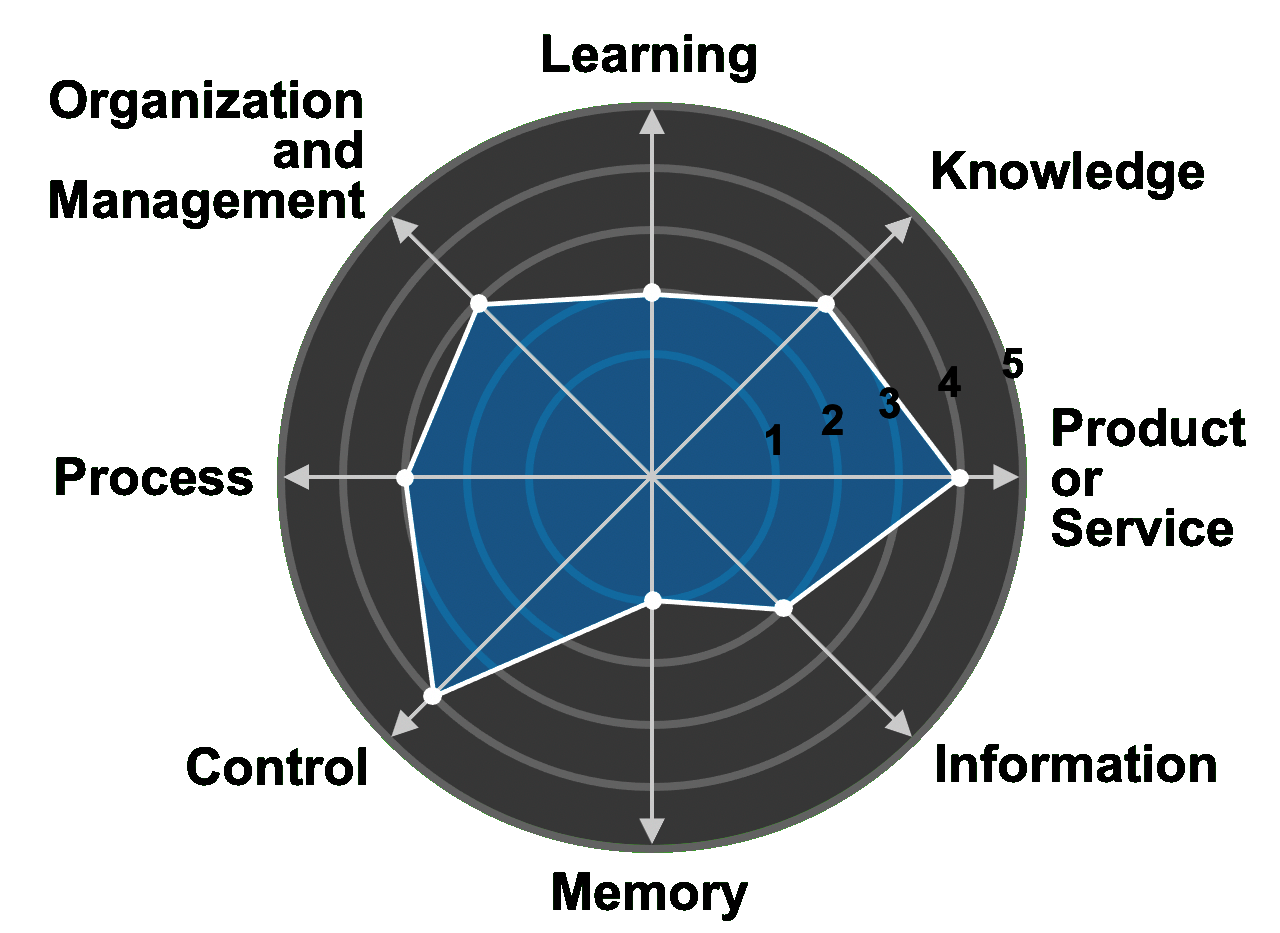

Self-steering employees and teams require navigation tools. CI offers a toolkit that gives access to well known and well documented methods. There are three main instruments:

Example of a strength/weakness analysis, using the CI compass.

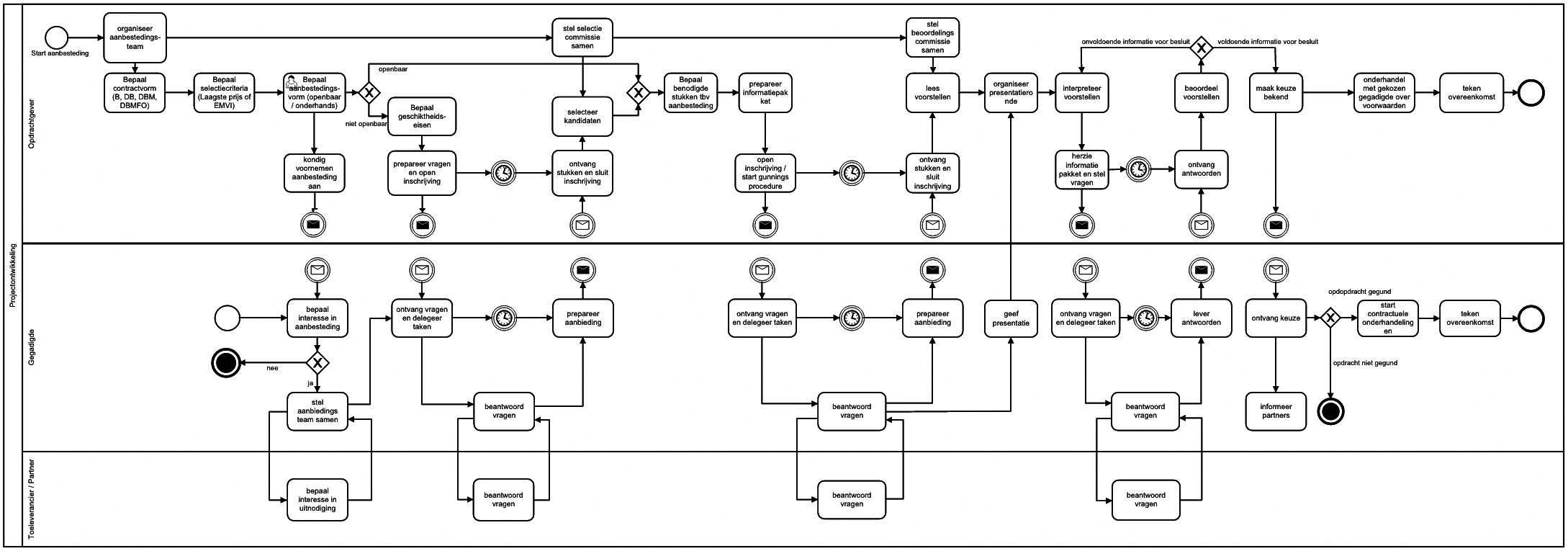

An example is the language BPMN (Business Process Model Notation). This is a graphical language for the description of processes. BPMN models can however also be 'understood' bij computer applications. With some additional work they are suited for the programming of workflow management systems and for the simulation of innovative business processes.

Related to BPMN is the language DMN (Decision Model Notation), which, as the name already suggests, supports the description of rules for decision making. Processes that are not too complicated can be automated with these two languages.

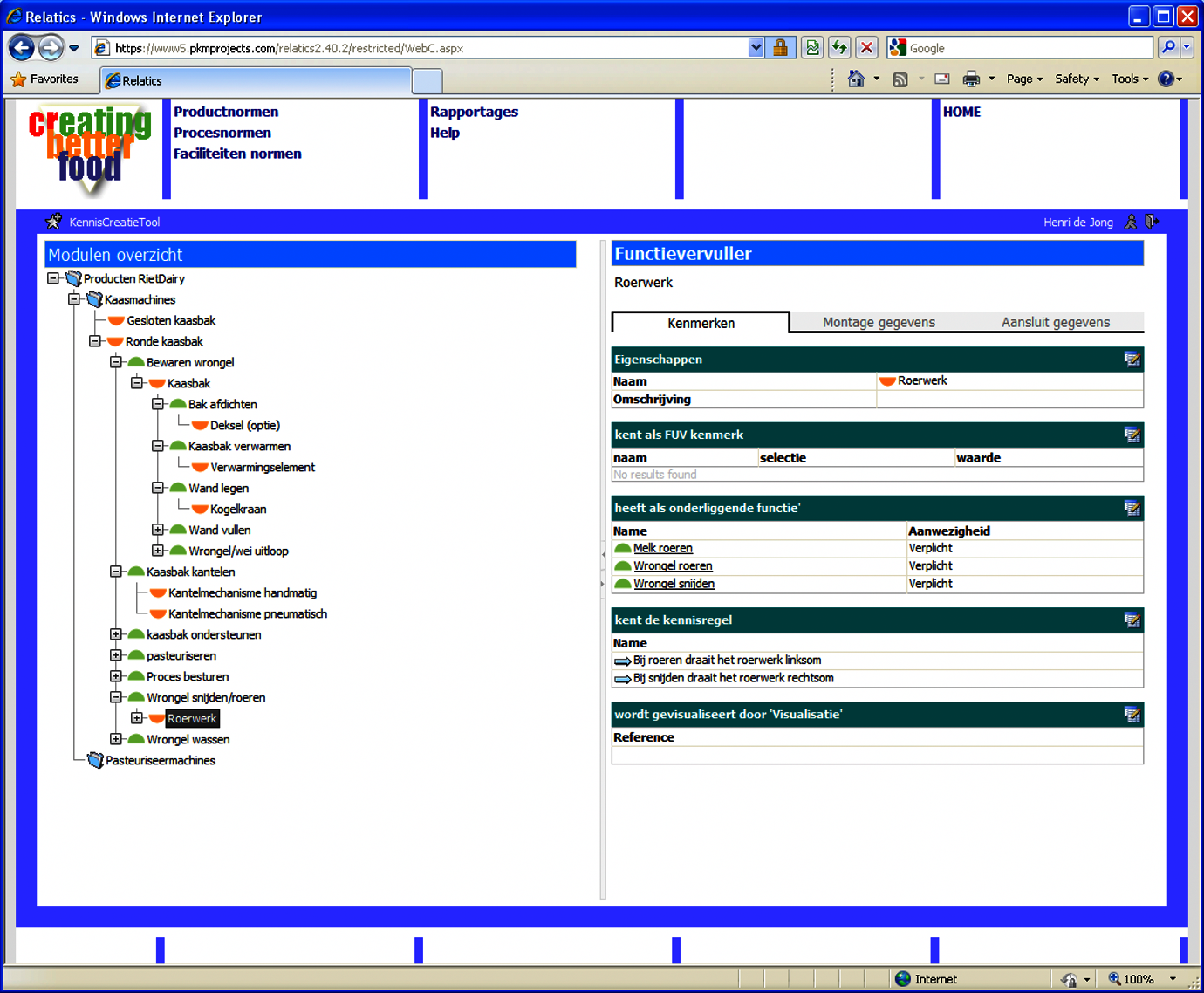

Other languages and notations are suited for the description of information or data, for the modelling of knowledge, or for the design of complex products.

The toolkit for Collaborative Innovation is therefore aligned with a new generation of technologies that support people and enterprises to develop customized software solutions quickly and at minimal cost.

Example of a process model in the language BPMN. It describes in Dutch the tender procedure of a public building project. This model was developed in the R&D project BMCB (Business Models for Circular Building) by branche organization VMRG (metal facades) and Real Capital Systems.

Example of a modular product structure, designed with the socalled 'Hamburger method', of a machine for the production of cheese. This model is developed in the R&D project 'Creating Better Food' of branche organisation GMV (producers of machines for the agriculture and food industry).

An important contribution to systems theory and organizational theory was developed by professors Jan in 't Veld (Fokker, TU Delft), Pierre Malotaux (TU Delft) and Ulbo de Sitter (TU Eindhoven, founder of the modern socio-technical systems theory).

Several specialized languages for the description of functions, processes, information, knowledge, product structures and organizations were also developed in the 70-ies and 80-ies. The US Air Force ICAM programme (ICAM = Integrated Computer Aided Manufacturing), placed several of them under one roof called IDEF (IDEF = Integrated DEFinition methods).

In the 90-ies a group of large technology companies, working together under the name OMG (OMG = Object Management Group) took the initiative to develop a series of modelling standards that were better suited for software development. Apart from OMG several other joint efforts arised for standardization of the internet infrastructure and the development of 'open source' information technology. Amongst the most important ones are W3C (the World Wide Web Consortium) and Apache Foundation.

The knowledge about all these methods remained however restricted to large companies and specialized consultancy firms. They were hardly accessible for medium and small companies, and they were not part of the curricula of schools and universities other than those specialized in informatics.

By the end of the 90-ies consultancy firm TLO Holland Controls developed a concept that makes this knowledge accessible for small and medium sized enterprises (SME's). Supported by coaches, students of professional schools make models of existing working practices of these companies, identifying bottlenecks and possibilies for improvement. Together with the employees they design new practices, including idea's for new products and services. An important advantage of this approach is that innovations are developed in a bottom-up fashion, by the people who eventually have to implement and execute them.

This concept, called "Methodisch Innoveren" in Dutch, is applied in dozens of companies in the ship building, machine building and installation industries, in collaboration with their respective branche organizations.

In 2004 Foundation-CI (in Dutch: Platform-IO) was founded by Wim Troost (founder and former CEO van ASM Lithography), Jan Hak (former owner and director of Hak vegetables, and chairman of GMV (Dutch association of manufacturers of machines for food processing)), Max Hoefeijzers (chairman of the Da Vinci college), Alexander Udink ten Cate (professor of Applied Systems Technology at Wageningen University), Piet de Bont (former chairman of Uneto-VNI, the association of suppliers of technical installations), Herman Eekels (former chairman Croon Electrotechnics) and Theo Lohman (former board member of KIVI, the Royal Dutch Association of Engineers), with the goal to promote the application of Collaborative Innovation in the Dutch industry.

The current board consists of Jan Hak (chairman), Onno-Hans Noteboom (senior business consultant at Arlande) and Wim Gielingh (owner and director of Real Capital Systems).